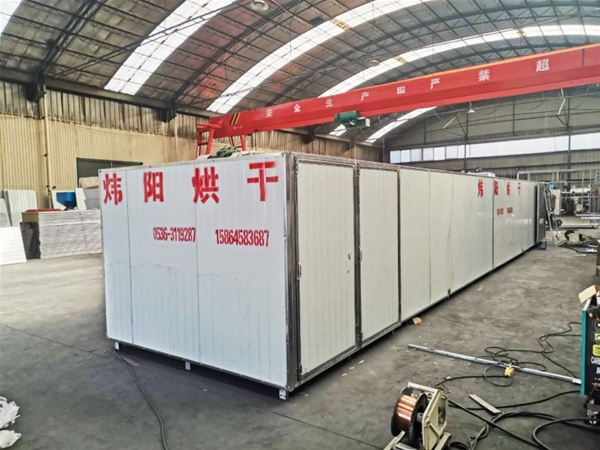

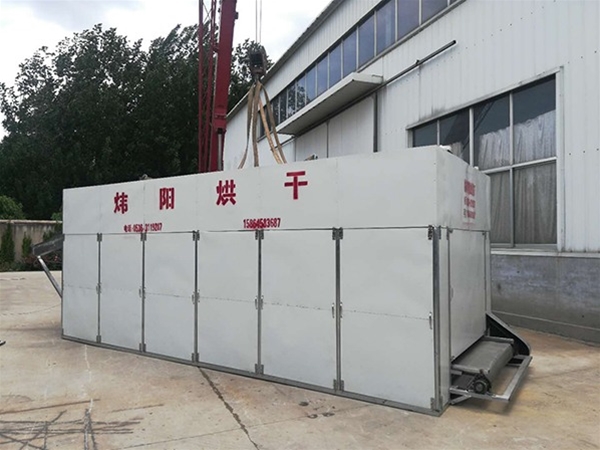

Product Name: WMH series split disassembly combined drying oven

Note: The wood oven has a powerful circulating airflow and flexible humidity regulation to ensure the quality and yield of various types of wood.

& nbsp;& nbsp;& nbsp; The WMH series wood hot air (steam) drying equipment can dry wood of various tree species, specifications, and purposes. It has the advantages of energy saving, safety, reliability, short drying cycle, good drying quality, and low drying cost. It is widely used in large, medium, and small wood processing enterprises, especially for manufacturers engaged in wood product export business& nbsp;

& nbsp;& nbsp;& nbsp; The WMH series wood drying equipment, during normal operation, the fuel is fully burned in the combustion chamber, generating heat energy, which is fully absorbed by the drying medium in the heat energy drying system, producing a temperature of about 170 degrees Celsius. Under the action of the circulating fan, the high-temperature airflow is transported to the drying chamber through the control system and conveying system to dry the wood. At the same time, the steam generation device on the equipment can generate a large amount of atmospheric steam. According to the requirements of the drying process, the steam can be timely sent into the drying chamber to spray steam and adjust the humidity of the wood. The humidity control system is an independent steam system and is equipped with safety devices. Saturated wet steam can quickly make the surface humidity and internal humidity of wood consistent, thereby achieving the goal of drying both the interior and exterior of wood simultaneously. For solid and heavy hard and thick wood, intermittent heating drying technology can be used to solve the defects such as internal cracking, end cracking, and deformation that occur during the drying process, greatly improving the yield of wood products.

& nbsp;& nbsp;& nbsp; The WMH series wood drying equipment is equipped with a thermal energy recovery system, which fully utilizes the drying medium and minimizes the heat loss caused by the emission of hot and humid air. The recycling and utilization of heat energy significantly reduces drying costs and shortens drying cycles.

Main technical parameters:

| model | Air outlet

Temperature ℃ | Fan power

KW | Heating device | Indoor temperature ℃ | Dried wood

Material moisture content | External dimensions m

long×wide×high

| Dry room net size m

long×wide×high |

| ZBX-8 | ≥170 | one point five | a set | ≥80 | 10% | five point five×two×two point five | four point five×two×two point five |

| ZBX-10 | ≥170 | two point two | a set | ≥80 | 10% | five point four×two point four×two point six | four point four×two point four×two point six |

| ZBX-15 | ≥170 | two point two | a set | ≥80 | 10% | seven point two×two.4×two point seven | six×two point four×two point seven |

| ZBX-20 | ≥170 | three | a set | ≥80 | 10% | six point five×four point five×two point seven | 5.2 ×four point five×two point seven |

| ZBX-25 | ≥170 | three | a set | ≥80 | 10% | seven×four point five×two point eight | five.3×4.five×two point eight |

| ZBX-30 | ≥170 | four | a set | ≥80 | 10% | eight×four point five×two point nine | six×four point five×two point nine

|

The above drying oven data is for reference only and can be designed according to user requirements.